James P. Womack

13 Books Written

Lean Solutions: How Companies and Customers Can Create Value and Wealth Together

by James P. Womack

Rating: 3.9 ⭐

• 2 recommendations ❤️

In this landmark new book, James Womack and Daniel Jones deconstruct this broken producer-consumer model and show businesses how to repair it.A massive disconnect exists between consumers and providers today. Consumers have a greater selection of higher quality goods to choose from and can obtain these items from a growing number of sources. Computers, cars, and even big-box retail sites promise to solve our every need. So why aren't consumers any happier?Because everything surrounding the process of obtaining and using all these products causes us frustration and disappointment. Why is it that, when our computers or our cell phones fail to satisfy our needs, virtually every interaction with help lines, support centers, or any organization providing service is marked with wasted time and extra hassle? And who among us hasn't spent countless hours in the waiting room at the doctor's office, or driven away from the mechanic only to have the "fix engine" light go on?In their bestselling business classic Lean Thinking, James Womack and Daniel Jones introduced the world to the principles of lean production -- principles for eliminating waste during production. Now, in Lean Solutions, the authors establish the groundbreaking principles of lean consumption, showing companies how to eliminate inefficiency during consumption.The problem is neither that companies don't care nor that the people trying to fix our broken products are inept. Rather, it's that few companies today see consumption as a process -- a series of linked goods and services, all of which must occur seamlessly for the consumer to be satisfied. Buying a home computer, for example, involves researching, purchasing, integrating, maintaining, upgrading, and, ultimately, replacing it.Across all industries, companies that apply the principles of lean consumption will learn how to provide the full value consumers desire from products without wasting time or effort -- theirs or the consumers' -- and as a result these companies will be more profitable and competitive.Lean Solutions is full of surprising success Fujitsu, a leading service company for technology, has transformed the way call centers solve problems -- learning how to eliminate the underlying cause of current problems rather than fixing them again and again. An extremely successful car dealership has adopted lean principles to streamline its business, making for dramatically reduced wait time, fewer return trips, and greater satisfaction for customers -- and a far more lucrative enterprise.Lean Solutions will inspire managers to take the first steps toward perfecting their company's process of giving consumers what they really want.

Lean Thinking: Banish Waste and Create Wealth in Your Corporation

by James P. Womack

Rating: 3.9 ⭐

• 2 recommendations ❤️

Expanded, updated, and more relevant than ever, this bestselling business classic by two internationally renowned management analysts describes a business system for the twenty-first century that supersedes the mass production system of Ford, the financial control system of Sloan, and the strategic system of Welch and GE. It is based on the Toyota (lean) model, which combines operational excellence with value-based strategies to produce steady growth through a wide range of economic conditions. In contrast with the crash-and-burn performance of companies trumpeted by business gurus in the 1990s, the firms profiled in Lean Thinking -- from tiny Lantech to midsized Wiremold to niche producer Porsche to gigantic Pratt & Whitney -- have kept on keeping on, largely unnoticed, along a steady upward path through the market turbulence and crushed dreams of the early twenty-first century. Meanwhile, the leader in lean thinking -- Toyota -- has set its sights on leadership of the global motor vehicle industry in this decade. Instead of constantly reinventing business models, lean thinkers go back to basics by asking what the customer really perceives as value. (It's often not at all what existing organizations and assets would suggest.) The next step is to line up value-creating activities for a specific product along a value stream while eliminating activities (usually the majority) that don't add value. Then the lean thinker creates a flow condition in which the design and the product advance smoothly and rapidly at the pull of the customer (rather than the push of the producer). Finally, as flow and pull are implemented, the lean thinker speeds up the cycle of improvement in pursuit of perfection. The first part of this book describes each of these concepts and makes them come alive with striking examples. Lean Thinking clearly demonstrates that these simple ideas can breathe new life into any company in any industry in any country. But most managers need guidance on how to make the lean leap in their firm. Part II provides a step-by-step action plan, based on in-depth studies of more than fifty lean companies in a wide range of industries across the world. Even those readers who believe they have embraced lean thinking will discover in Part III that another dramatic leap is possible by creating an extended lean enterprise for each of their product families that tightly links value-creating activities from raw materials to customer. In Part IV, an epilogue to the original edition, the story of lean thinking is brought up-to-date with an enhanced action plan based on the experiences of a range of lean firms since the original publication of Lean Thinking. Lean Thinking does not provide a new management "program" for the one-minute manager. Instead, it offers a new method of thinking, of being, and, above all, of doing for the serious long-term manager -- a method that is changing the world.

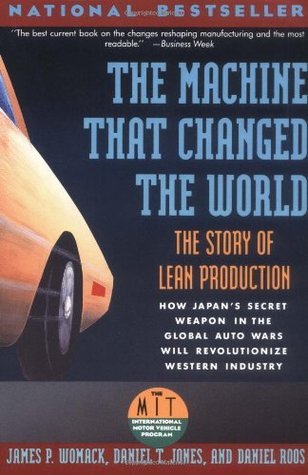

Based on the Massachusetts Institute of Technology's five-million-dollar, five-year study on the future of the automobile, a groundbreaking analysis of the worldwide move from mass production to lean production. Japanese companies are sweeping the world, and the Japanese auto industry soars above the competition. Drawing on their in-depth study of the practices of ninety auto assembly plants in seventeen countries and their interviews with individual employees, scholars, and union and government officials, the authors of this compelling study uncover the specific manufacturing techniques behind Japan's success and show how Western industry can implement these innovative methods. The Machine That Changed the World tells the fascinating story of "lean production," a manufacturing system that results in a better, more cost-efficient product, higher productivity, and greater customer loyalty. The hallmarks of lean production are teamwork, communication, and efficient use of resources. And the results are remarkable: cars with one-third the defects, built in half the factory space, using half the man-hours. The Machine That Changed the World explains in concrete terms what lean production is, how it really works, and--as it inevitably spreads beyond the auto industry--its significant global impact.

“The life of lean is experiments. All authority for any sensei flows from experiments on the gemba [the place where work takes place], not from dogmatic interpretations of sacred texts or the few degrees of separation from the founders of the movement. In short, lean is not a religion but a daily practice of conducting experiments and accumulating knowledge.”So writes Jim Womack, who over the past 30 years has developed a method of going to visit the gemba at countless companies and keenly observing how people work together to create value. Over the past decade, he has shared his thoughts and discoveries from these visits with the Lean Community through a monthly letter. With Gemba Walks, Womack has selected and re-organized his key letters, as well as written new material providing additional context.Gemba Walks shares his insights on topics ranging from the application of specific tools, to the role of management in sustaining lean, as well as the long-term prospects for this fundamental new way of creating value. Reading this book will reveal to readers a range of lean principles, as well as the basis for the critical lean practice of: go see, ask why, and show respect.Womack explains: - why companies need fewer heroes and more farmers (who work daily to improve the processes and systems needed for perfect work and who take the time and effort to produce long-term improvement) - how “good” people who work in “bad” processes become as “bad” as the process itself - how the real practice of showing respect comes down to helping workers frame and solve their own problems - how the short-term gains from lean tools can be translated to enduring change from lean management. - how the lean manager has a “restless desire to continually rethink the organization’s problems, probe their root causes, and lead experiments to test the best currently known countermeasures”By sharing his personal path of discovery, Womack sheds new light on the continued adoption and development of the most important new business system of the past fifty years. His journey will provide courage and inspiration for every lean practitioner today.

By identifying all the steps and time required to move a typical product from raw materials to finished goods, the authors show that nearly 90 percent of the actions and 99.99 percent of the time required for the value chain's Current State create no value. In addition, the mapping method clearly shows demand amplification of orders as they travel up the value stream, steadily growing quality problems, and steadily deteriorating shipping performance at every point up stream from the customer. The mapping methodology takes managers step-by-step through an improvement process that converts the traditional value stream of isolated operations into an ideal future-state value stream in which value flows from raw materials to customer in just 6 percent of the time previously needed. The dramatically improved value stream also eliminates unnecessary transport links, inventories, and handoffs, the key drivers of hidden connectivity costs. Applying the method to a realistic example, the authors show how four firms sharing a value stream can create a win-win-win-win-win future in which everyone, including the end consumer, can be better off.

"Pain and Suffering are inevitable, but misery is optional." I once saw this motivational statement on a running shirt. I liked it and subscribed to it during my time as an ultra marathoner. When I reunited with my sweetheart from 1967 and married her in 2005, I began to understand that phrase in a new and challenging way. Harriette Burnette and I met and enjoyed a love affair in the summer of 1967. We lost touch and lived separate lives for thirty-eight years. During that time we lived very different and challenging lives. She suffered through a series of painful family and personal losses while raising two children on her own. I fought battles with depression, alcoholism, and professional dissatisfaction. Ultimately, after thirty-two years, my marriage ended in a divorce as well. During our separate, but incredibly similar experiences in life, we each held the belief that life still had something special in store for us. In 2005, through a series of unusual events, I made contact with Harriette after a thirty-eight year hiatus. Our subsequent reunion, courtship, and marriage made us believe that a power greater than ourselves worked in our lives to fill our needs and work miracles for us. Little did we know that, when we said, "I do" on that cold day in 2005, we were about to hop on one of life's most frantic, harrowing, and unimaginable rides. We both discovered the true meaning of pain as well as suffering and learned how our reactions to life's challenges can forever change lives. We took the pain and suffering, but we decided that misery just could not be an option. Jim Womack is a native of Botetourt County, Virginia and a graduate of Virginia Tech, where he studied Civil War History under the noted historian Dr. James I Robertson. Jim taught history at James River High School in Botetourt County for twenty-eight years before retiring in 2003. From 2000 until 2005, he trained for and ran many ultra marathons in central Virginia and elsewhere as well as traveled and backpacked around the western United States. In 2005, he reunited with his sweetheart from 1967 and entered a new and wonderful life with his new bride, Harriette. Shortly afterward, he learned that he had cancer and that his life would drastically change. Together, Jim and Harriette enjoy the providential love which they have found and continue to work together to build a special home for themselves and their families. As more and more people heard their remarkable story of love lost and love regained, Jim decided to write down their story and share their marvelous journey as a tribute to their individual and collective triumphs over disease and disappointment. In addition to From One Man's Heart, Jim also published a collection of student bloopers entitled When Misquotes Bit You. He is in the process of writing short stories about his youth in Botetourt County, his outdoor experiences, and his new life in Northern Virginia with Harriette. He plans to release one new volume each year.

Penser l'entreprise au plus juste

by James P. Womack

リーン生産方式が、世界の自動車産業をこう変える。―最強の日本車メーカーを欧米が追い越す日

by James P. Womack

SYSTEME LEAN 2E EDITION PENSER L'ENTREPRISE AU PLUS JUSTE

by James P. Womack

Leather Binding on Spine and Corners with Golden Leaf Printing on round Spine (extra customization on request like complete leather, Golden Screen printing in Front, Color Leather, Colored book etc.) Reprinted in 2018 with the help of original edition published long back [1979]. This book is printed in black & white, sewing binding for longer life, printed on high quality Paper, re-sized as per Current standards, professionally processed without changing its contents. As these are old books, we processed each page manually and make them readable but in some cases some pages which are blur or missing or black spots. If it is multi volume set, then it is only single volume. We expect that you will understand our compulsion in these books. We found this book important for the readers who want to know more about our old treasure so we brought it back to the shelves. Hope you will like it and give your comments and suggestions. - English, Pages 70. COMPLETE LEATHER WILL COST YOU EXTRA US$ 25 APART FROM THE LEATHER BOUND BOOKS. {FOLIO EDITION IS ALSO AVAILABLE.} An examination of the transit funding process at the local level : final report / James P. Womack, Alan A. Altshuler ; Center for Transportation Studies, Massachusetts Institute of Technology ; prepared for U.S. Department of Transportation, Urban Mass Transportation Administration. 1979 [Leather Bound] by Womack, James P.

Lean Thinking: Banish Waste and Create Wealth in Your Corporation, Revised and Updated

by James P. Womack

Expanded, updated, and more relevant than ever, this bestselling business classic by two internationally renowned management analysts shows how companies of any size in any industry can seize opportunities in the post-bubble economy. Instead of constantly reinventing business models, lean thinkers go back to basics by asking what the customer really perceives as value. The next step is to line up value-creating activities for a specific product along a value stream while eliminating activities (usually the majority) that don't add value. Then the lean thinker creates a flow condition in which the design and the product advance smoothly and rapidly at the pull of the customer (rather than the push of the producer). Finally, as flow and pull are implemented, the lean thinker speeds up the cycle of improvement in pursuit of perfection. The first part of this book describes each of these concepts and makes them come alive with striking examples.Lean Thinking clearly demonstrates that these simple ideas can breathe new life into any company in any industry in any country. But most managers need guidance on how to make the lean leap in their firm. Part II provides a step-by-step action plan, based on in-depth studies of more than fifty lean companies in a wide range of industries across the world.Even those readers who believe they have embraced lean thinking will discover in Part III that another dramatic leap is possible by creating an extended lean enterprise for each of their product families that tightly links value-creating activities from raw materials to customer.In Part IV, an epilogue to the original edition, the story of lean thinking is brought up-to-date with an enhanced action plan based on the experiences of a range of lean firms since the original publication of the book.

Lean Consumption

by James P. Womack

Managementwissen zum Hören mit dem Harvard Business ManagerNutzen Sie Ihre Zeit optimal. Lassen Sie sich den Harvard Businessmanager vorlesen. So können Sie sich Wissen aneignen, auch wenn Sie keine Zeit zum Lesen haben. Ab sofort erscheinen hier regelmäßig neue Audio-Beiträge aus dem Harvard Business Manager.Das Prinzip der Lean Production revolutionierte die Herstellung von Waren. Nun ist die Zeit reif, diese Denkweise auch auf Konsumprozesse anzuwenden. Denn mit ihren Einkäufen wollen die Kunden meist nur alltägliche Probleme lösen. Unternehmen, die ihren Kunden dabei helfen, sparen allen Beteiligten Zeit und können hohe Gewinne erzielen, wie die beiden Autoren James P. Womack und Daniel T. Jones zeigen werden.(c) 2005 Harvard Business Manager

[Lean Thinking: Banish Waste and Create Wealth in Your Corporation] (By: James P. Womack) [published: August, 2003]

by James P. Womack

![An examination of the transit funding process at the local level : final report / James P. Womack, Alan A. Altshuler ; Center for Transportation Studies, Massachusetts Institute of Tec [Leather Bound]](https://m.media-amazon.com/images/S/compressed.photo.goodreads.com/books/1699297796i/149682410.jpg)